Maggiori Fratelli is a company specialised in metalworking. We are a well-established company, but by no means a static one: we are extremely versatile, constantly evolving and always up to date. We meet the growing and ever-changing requests of our customers by offering an effective, quality service.

Targeted investments, technological development and a highly strategic family business have enabled the company to expand and adopt new machinery to perform new processes. Our activities include metal spinning, shearing and deep drawing, laser cutting and metal finishes, with quality always being our signature trademark.

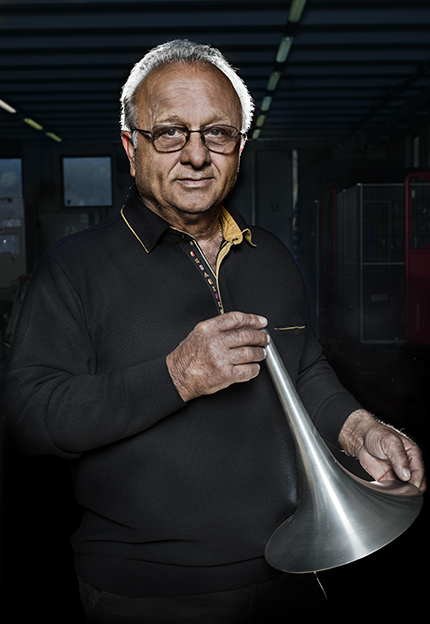

Maggiori Fratelli was born in 1962, when Angelo and Mario Maggiori, two brothers, both specialised in metal spinning, realised their project; they opened a metal spinning company in Nave, in the province of Brescia.

They initially did all the work completely by hand. Over the years, by combining their passion and years-long experience, the two brothers improved their technology: in 1990 they purchased their first Nova Sidera Giotto 400 Computerised Numerical Control metal spinner. Given the versatility, speed and great precision in working on details, they decided to continue investing in technology by purchasing other CNC metal spinners. By 2005 the company had grown in size and purchased 2,000 sqm of new buildings.

So they added CNC presses and shears to their machinery inventory; they also inaugurated the mechanical workshop department dedicated to the in-house construction of equipment, moulds and small batch production.

In 2012, Angelo’s children, Lara, Jacopo and Mattia, who had grown up in this environment, decided to take the reins of the company and founded the new Maggiori Fratelli Srl. They added new machinery, including more CNC metal spinners such as the Super Tornio Vega 600 Nova Sidera, which can spin up to 10 mm of stainless steel and up to 15 mm of aluminium, as well as presses and a CNC cutting line to cut extruded profiles. Moreover, they added a teach-in CNC lathe to the mechanical workshop department to build ever more precise moulds and a machining centre with pallet changer for medium-size production.

The constant evolution of Maggiori Fratelli enabled the company to obtain the certification of the UNI EN ISO 9001 Quality System.

In 2020, a new metal shearing, deep drawing and finishing department was purchased and installed with 3 new hydraulic presses and 5 mechanical presses, 3 edgebanders, a robotic island for polishing, grinding, satin finishing, and an automatic metal polishing machine.

There is then a new 1300 m warehouse in which in 2022 we installed the new Trumpf Fibra 3000W machine for fibre laser cutting and a new technical office for designing activities, as well as a new department dedicated to the mounting, assembly and quality control of our products.

HISTORY

Our journey began 50 years ago,

and the growth has been non-stop.

PROFESSIONALISM

For us, knowing how to do something means satisfying each of our customers in the best way possible.

VERSATILITY

We transform any idea into a project, with any type of metal.

PRECISION

We check every single detail in the work we do.

OUR HISTORY

1962

FOUNDATION

Angelo and Mario Maggiori found their manual metal spinning company in Nave, in the province of Brescia.

1990

TECHNOLOGICAL DEVELOPMENT

Maggiori Fratelli purchases its first CNC spinning lathe: the Nova Sidera Giotto 400.

2000

SUCCESS AND

NEW INVESTMENT

The versatility, the speed and the great precision in the creation of parts by the lathe purchased convinces the company to purchase another CNC spinning lathe.

2003

NEW TECHNOLOGY

The company continues the path of technological development and invests in a new machine: the Nova Sidera Hercules 400 lathe.

2005

COMPANY EXPANSION

Maggiori Fratelli expands with 2,000 m2 of new factory space. New CNC presses, shears and cutters join its machine inventory. Finally, it develops the in-house mechanical workshop for the construction of tooling and moulds and for small production runs.

2012

THE NEW

MAGGIORI FRATELLI SRL

Angelo’s sons, Lara, Jacopo and Mattia, who grew up in this company, take up the reins of the company when their father and uncle decide to enjoy a well-deserved retirement. They add new machinery including another CNC spinning lathe, new presses, shears and a CNC cutting line for extruded profiles. They also equip the mechanical workshop with a teach-in CNC lathe for the construction of more precise moulds and a Machining Centre with a Pallet Changer for medium-scale production.

2017

SUPER SPINNING

LATHE VEGA 600

The company adds to its spinning lathe machinery the Super Lathe Vega 600 Nova Sidera, capable of turning up to 10 mm of stainless steel and up to 15 mm of aluminium. Furthermore, it decides to take the path to certify its quality system according to the UNI EN ISO 9001 standard.

2019

QUALITY SYSTEM

CERTIFICATION

The Company obtains the EN ISO 9001 Quality System Certification, an international reference standard for quality management.

2020

NEW METAL CUTTING, DEEP DRAWING AND FINISHING DEPARTMENT

Maggiori Fratelli created a new metal shearing, deep drawing and finishing department with 3 new hydraulic presses and 5 mechanical presses, 3 edgebanders, a robotic island and an automatic metal polishing machine.

2022

NEW LASER CUTTING, TECHNICAL OFFICE, MOUNTING AND ASSEMBLY DEPARTMENT

Our company installed a new Trumpf Fibra 3000W machine for fibre laser cutting in a new warehouse and a new technical office dedicated to designing activities, as well as a department dedicated to the mounting, assembly and quality control of our products.

1962

1990

2000

2003

2005

2012

2017

2019

2020

2022

Team

ANGELO MAGGIORI

JACOPO MAGGIORI

LARA

MAGGIORI

MATTIA MAGGIORI